I was given some UK grown Columbus hops by @_aka_hige that were grown by by some of his friends, and so I thought I would make a nice US IPA body to try and showcase them.

OK, so I've not been updating this blog recently, that's because of brew kit changes over the past few months, and for that I'm sorry. I'm at a point where I am having to experiment and work out consistent values for certain aspects of my brew kit, which I'd got sorted on my old kit. I should have been blogging the hell out of my changes and upgrades, and showing you what I'm going through.

For this beer, I decided to add body and colour to the beer with malts that I don't usually use, I wanted to give an American aspect to the UK brewed beer, as I was using UK grown US hops.

I used the following malts;

5kg of Marris Otter

300g of Lager Malt

126g of CaraMunich

120g of Carapils

121g of Crystal 150

The crystal was there to give the beer the colour, flavour, and hopefully toffee sweetness that good US IPA's have. The malt bill gave me 1212 gravity points, and going into an aimed 24 litre batch size, that would give me an OG of 1.051.

As a pass forward from my old kit, I use certain values as constants, such as evaporation volume, hop loss, grain loss. These stood me well for the last kit, it seems I need to re-evaluate them for this kit though, as the results don't match those values.

As there was 5.667kg of malt, I mashed in with 14.2 litres of water (a ratio of 2.5 litres per kg) at a strike temperature of 74.3°C to give me a mash temperature of 64°C (my grain was at 14°C). I'm mashing a little warmer now, to give a bigger, and hopefully better, body to my beers.

I "sparged" with 20.4 litres of liquor at 74°C, I use quotation marks, as I cover the grain bed with foil that I have poked holes through, and pour the liquor in. I still haven't got my sparge-arm rotating yet.

I got 194g of these UK grown hops, so I wanted to use them for the late additions and dry hopping, so I bittered with 10g of Magnum hop, and then proceeded to boil for 40 minutes without another addition.

With 20 minutes left, the hop addition became as such;

20 - US Columbus - 25g

15 - US Columbus - 25g

10 - US Columbus - 25g

05 - UK Columbus - 44g

00 - UK Columbus - 50g (Flameout)

And, I will add in 100g for the dry hopping.

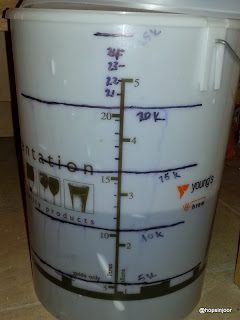

One of the things I've noticed with my new kit is a difference in the volumetric output from the MT, so I need a way to accurately tell what I put in, and get out. Thus I spent a bit of time and weighed the liquor as it went into the HLT/kettle, and then measured the same when it came out of the MT, from this, I put markings on the bucket in kg.

This will hopefully allow me to work out various values for my system, and evaluate the constants to make this a doddle again.

So, I was aiming at a batch size of 24 litres, which from the old system required 14.2 litres of Mash liquor, and 20.4 litres of sparge liquor, to give me a pre-boil volume of 28.3 litres.

Well, I used those values and I got out of the MT 29 litres of wort with an OG of 1.043 (10.8 brix on my refractometer). That's not too bad, that just means I need a slight adjustment on the grain loss values.

From the old system, I had evaporation and hop losses at 4.3 litres. That would have given me a final batch volume of 24.7 litres, slightly over what I aimed for, but all cool.

It didn't work out that way, I got 23 litres finished, though that did include a stuck copper with the last 3 litres. Bloody annoying, to say the least.

My run-off looked like this, using my counter-flow wort chiller that I made over the summer.

The run-off was pretty damn clear, it was see through (usually a good indication).

I ended up with 23 litres post boil, and with a gravity of 13.6 brix, or 1.055. This was 0.004 higher than expected, but the volume finished was lower.

I am recording all this so that I can be more accurate with my spreadsheet, so I checked it, and with a batch volume of 23, I should have got 1.053 at 70% efficiency. So I'm getting a decent efficiency, and also good data for the future of my spreadsheet. I see this as a good scientific thing.

I'm hoping for big pithy orangey flavours. Hopefully, I shall let you know how it goes. I'll try to keep this blog more up-to-date.

Enjoy.

I "sparged" with 20.4 litres of liquor at 74°C, I use quotation marks, as I cover the grain bed with foil that I have poked holes through, and pour the liquor in. I still haven't got my sparge-arm rotating yet.

I got 194g of these UK grown hops, so I wanted to use them for the late additions and dry hopping, so I bittered with 10g of Magnum hop, and then proceeded to boil for 40 minutes without another addition.

With 20 minutes left, the hop addition became as such;

20 - US Columbus - 25g

15 - US Columbus - 25g

10 - US Columbus - 25g

05 - UK Columbus - 44g

00 - UK Columbus - 50g (Flameout)

And, I will add in 100g for the dry hopping.

One of the things I've noticed with my new kit is a difference in the volumetric output from the MT, so I need a way to accurately tell what I put in, and get out. Thus I spent a bit of time and weighed the liquor as it went into the HLT/kettle, and then measured the same when it came out of the MT, from this, I put markings on the bucket in kg.

This will hopefully allow me to work out various values for my system, and evaluate the constants to make this a doddle again.

So, I was aiming at a batch size of 24 litres, which from the old system required 14.2 litres of Mash liquor, and 20.4 litres of sparge liquor, to give me a pre-boil volume of 28.3 litres.

Well, I used those values and I got out of the MT 29 litres of wort with an OG of 1.043 (10.8 brix on my refractometer). That's not too bad, that just means I need a slight adjustment on the grain loss values.

From the old system, I had evaporation and hop losses at 4.3 litres. That would have given me a final batch volume of 24.7 litres, slightly over what I aimed for, but all cool.

It didn't work out that way, I got 23 litres finished, though that did include a stuck copper with the last 3 litres. Bloody annoying, to say the least.

My run-off looked like this, using my counter-flow wort chiller that I made over the summer.

The run-off was pretty damn clear, it was see through (usually a good indication).

I ended up with 23 litres post boil, and with a gravity of 13.6 brix, or 1.055. This was 0.004 higher than expected, but the volume finished was lower.

I am recording all this so that I can be more accurate with my spreadsheet, so I checked it, and with a batch volume of 23, I should have got 1.053 at 70% efficiency. So I'm getting a decent efficiency, and also good data for the future of my spreadsheet. I see this as a good scientific thing.

I'm hoping for big pithy orangey flavours. Hopefully, I shall let you know how it goes. I'll try to keep this blog more up-to-date.

Enjoy.

No comments:

Post a Comment